First published in High Country News, Sept. 16, 1985; the sawmill job had been in the late 1970s.

Sawmill I: Working the Gate between Worlds

In the realm of interesting things that confuse me and confusing things that interest me, the relationships between trees and humans are high on my list.

As with almost all plant-and-animal relationships, we humans come off as dependents – we need the trees a lot more than the trees need us. At the most basic level there’s the oxygen they pump out. They aren’t the only source of oxygen on earth, but they are certainly an important one. This is some mutuality to this dependency since they need the carbon dioxide we generate – and we have become substantial generators of carbon dioxide; studies currently indicate that most tree species are appreciating this and are doing what they can to take care of all that extra carbon dioxide.

But in all our other interactions with trees, they are serving us, usually in some way that demands a high level of sacrifice from them. Our least demanding uses for trees are when we use them for shade, windbreaks, and aesthetic decoration – we actually do a lot to nurture and protect them in those instances, and even to help them spread into places where they previously weren’t found.

But our other principal uses for trees are for fuel and shelter, and in those uses the trees get “changed” in the most Biblical sense. Fuelwood is still the number one use of trees around the world, and a lot of land has been desertified over time just to keep humans warm and fed. Civilizations have fallen apart from that most elemental “energy crisis.”

Our own Euro-American civilization suffered that energy crisis a century or so before we began to move to America. My surname, in fact, implicates my ancestors in that energy crisis. I’ve parsed it etymologically: “Sibb-leah” is what “Sibley” came from (the Old-English “leah” became “ley” in Middle English). Both root words are in the dictionary today: one’s “sibb” is one’s clan or kin group; “leah” (or just “lea”) is a meadow. So “clan of the meadow,” or maybe just “people of the meadow.”

But now take “meadow” back into my ancestral prehistoric Anglo-Saxon England and Europe, which was allegedly so densely forested that an energetic and focused squirrel could supposedly cross either going tree to tree without ever touching ground. Undoubtedly an exaggeration. But in that environment, the “meadow” becomes a “clearing in the forest.” And take “leah” back into the less refined grunts and sibilations of the Indo-European proto-tongue that birthed languages from India to Iceland, and you got a sound which probably underlies the words for “light” in many of those languages – thus, “the place where light comes into the forest.”

When the American Sibb-leahs went into the great forests of North America – and we’ve been here since 1629 – that’s the way we, in part, justified our devastations: “letting the light into the forest” was what the tree-mining loggers said they were doing, opening the land up for farming, recreating in our “New England” the landscapes of the old England.

So that is pretty exactly what my name means: Sibley, the Sibb-Leah, the people who let the light into the forest. Eventually we left England for new forests in part because there was no more forest to let the light into; it was basically all meadow, and people were sneaking out at night to tear up hedgerows, dismantle bridges, because wood was still the primary energy source for heat and cooking – a big chronic energy crisis that gradually drove the people to the dirty work of mining coal for fuel.

And despite an avowed love for trees, I have not really departed far from that ancestral pattern of “letting light into the forest.” For the past half century I have depended partially or entirely on wood for heat. We installed a wood stove in our current “modern” gas-heated house mostly because I don’t feel that comfortable depending on a bunch of petrocapitalists a state or two distant to deliver my energy. (Suppose they get a better offer elsewhere?)

Also, for maybe a quarter of those years, I have made part or all of my living from construction and carpentering, and I am not so naive as to not know where boards come from. Like all carpenters, I have shaken my head, and cussed a little, at the quality of some of the boards from the lumberyards today, as though it were the boards’ fault that the boards are not better. I saw a “clear” (knot-free) 20-foot white pine two-by-twelve, still as straight as when it was cut, in the old sawmill museum at Cook’s Forest Preserve near where I grew up in Western Pennsylvania, and I felt the mix of lust and longing any wood butcher would feel who has dealt with late-20th-century two-by-sixes.

Boards of course don’t really look like trees. Our modern shelters, in fact, have come to the point where they pretty much disguise and deny any direct relationship with anything so natural as a tree; the smooth flat surfaces, straight lines and squared corners jive aesthetically with the effort to create a constant mild climate within walls totally independent of the natural climate outside the walls. The shape of the boards as well as their function serve the purpose of establishing closed spaces that are independent of nature’s way of doing things.

It’s said there is “no such thing as a straight line in nature” – or a perfectly flat or perfectly smooth surface. That’s not strictly true; many rock crystals have edges as straight as anything manmade, and I’ve seen sheet mica that does smooth and flat very well. It is probably the most dependable characteristic of nature that it always violates, sooner or later, somewhere or other, any absolute statement about what it is or isn’t. But it is accurate enough to say that nature in general does not share our human fascination with straight lines, squared corners and smooth surfaces.

And the disconnect between tree and board that results from the way we transform trees into boards enables someone like me to develop, on the one hand, into something of a tree-hugger with a great love for trees and forests, but on the other hand, as a carpenter, turning the broken bodies of trees into one-family houses big enough to have sheltered whole hunter-gatherer “sibbs.” So the question arises: can one love both trees and good boards?

I actually got a chance to explore that question in some depth. In the course of my freelancing and oddjobbing career, I often had better breaks at oddjobbing than I was having at freelancing, and in one of those times when I needed something to put groceries on the table (not to mention a roof over the table), the husband of a friend happened to need a sawyer for a small sawmill he ran on his ranch.

Luce Pipher was the rancher’s name, and he was a story or two himself – stories for another day. His ranch was the last piece of private land up on the edge of Black Mesa between the Upper Gunnison River and the Smith Fork of the Gunnison, on a creek which just a few hundred yards downstream from the ranch poured in a waterfall into the Gunnison’s Black Canyon – you could, in fact, see the far rim of the canyon from the bedroom window of our cabin at Pipher’s sawmill. Between the Black Canyon National Park, the Gunnison National Forest, and odd lots of land under the Bureau of Land Management, Pipher was more or less surrounded by public lands – but refused philosophically to seek grazing permits for any of that land; he ran his cattle on land he picked up or leased here or there around the valley.

Luce’s father ran the kind of barefoot and bare-knuckle family where they stopped feeding you when you got to your middle teens, so Luce left home then, but came back a few years later and bought out his father. Cattle ranching was Luce’s first love, but he had all kinds of things going on the side to subsidize the ranching operation, and the sawmill was one of those things – a little operation employing two to five people (including the logger) and capable of cutting maybe a couple hundred-thousand board feet of rough-sawn, sun-dried lumber a year.

I knew nothing about milling lumber, or the machinery involved, but Luce wasn’t that impressed by my ignorance – and I reminded myself that I did have a Liberal Arts degree, which is supposed to prepare you to figure out anything the world can throw at you.

“You’ll learn fast, one way or the other,” he said the day I showed up to work. “Just go slow at first and try not to wreck anything.” He gave me a twenty-minute walking tour of the machinery, showed me how to turn the various parts on and off, and ran a couple logs through the saw to give me the basic idea, then went back to his beloved cows and left me to some intensive on-the-job self-training.

I took it slow the first couple weeks; I was so logically and rightly scared by the machinery that it was a month or so before I started to be reasonably comfortable with those singing blades a couple feet from where I timidly pulled and pushed the levers and buttons that moved big tree bodies around and into their transformations.

The centerpiece of the mill was of course the saw itself, a circular blade four feet in diameter with a circumference of chisel teeth. It ran off a big old antique electric motor that was, in turn, powered by a big old antique diesel generator. A set of belts and electrically-controlled hydraulic elements pulled logs mounted on a carriage into the saw. Getting the log onto the carriage was all done by muscle power, with canthooks to lever the log around. Except for the teeth on the saw, the mill was entirely built from used parts, but beautifully and tightly assembled by a “master of junk” in Crawford.

But the saw was the point of it all. The first time I looked at the saw close up that first day, it was in repose, and did not, to tell the truth, look that impressive. It didn’t look flat and hard, like the sawblade in my little skill saw; instead, it looked a little warpedy, dished – alarmingly floppy, in fact. I mentioned this to Pipher that first day.

“That’s right,” he said. He went over to it, grabbed it between a couple of its chisel teeth, and shook it; the saw flexed, bawong, bawong, like a big pizza pan. “It doesn’t stand up,” he said, “until it’s revving at speed – 720 rpm.”

“Doesn’t stand up”? My limited experience with steel had left me with the impression of something solid, hard and rigid, But I learned – and was to have the lesson driven home often in the months ahead – that a piece of steel four feet in diameter, spinning at 720 rpm, acts more like the pizza dough than the pizza pan. Under that much centrifugal force, its outer molecules tend to spread apart a little farther than its more central molecules. So in order for a saw to run flat and true at its operating speed, it has to be carefully hammered into a slightly cupped shape at rest.

He showed me: we fired up the diesel generator, then threw the head-rig switch; the generator lugged, then revved as the mill’s vintage electric motor overcame the inertia of the saw and got it to turning. For about 10 uneasy seconds, the saw picked up speed with a sound that can best be described as beating on the air. Then, it visibly and audibly “stood up” – straightened out in its motion, and the sound of beating against the air changed to a smooth hiss.

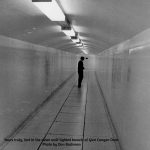

It gradually occurred to me in the following weeks and months that, when the saw stood up, it become something more than just a spinning sheet of metal; it became the force at a gate between worlds – the world of nature on one side of the saw, as represented by the logs on the deck: rough, barky elements from that naturally evolved world whose shapes and textures were all derived from eons of ad hoc cooperation and competition for light and water, accommodation to other plants, adaptation to challenges, and probably instances of cosmic genetic inspiration.

But on the other side, beyond the saw, were the logs transformed into boards: all lines, planes and hard square edges, for assembly into the linear and planar shapes and smooth textures that hardly existed in the world before man came along.

In the two-plus years I sawed for Pipher, I never really lost my sense of amaze on making the first cut on a log: there was the log on the saw carriage, and there was the saw; I moved the log into the saw’s space, and . . . except for the sudden increase of noise, nothing changed; it seemed as if the log and the saw were occupying the same space without affecting each other, holographic images just passing through each other – until I completed the cut and the slab fell away from the log, exposing a pale smooth plane and the log forever changed.

It reminded me of the pictures in my high-school geometry text: line drawings of Euclid’s plane, passing like a pane of glass through cones and cylinders to create the parabolas and hyperbolas of the conic sections. In the book, the pictures seemed quite abstract, devoid of reality. But there in the mill, there was the elongated conic cylinder in the rough, shaggy, lumpy and uneven form of the log – and then after the first cut, a smooth Euclidean parabola imposed on the log. The abstraction was the saw itself, the gate between realities: the saw was geometry incarnate, the powerful realization of abstractions found hardly anywhere in nature but in the minds of humans.

I quickly learned, however, both in the sawing process and then watching the lumber sun-dry in the yard, that the transformation from rough natural tree to smooth geometric board was hardly total or perfect: a lot of the tree passed through that gate to haunt the boards. Knots from branches that were important to the tree were very counter-productive in the smooth planes and lines of the board, sometimes even falling out when they dried. And the struggles of the tree to grow straight up on a sidehill, against the pressures of snow creep, uneven shading from other trees, and other natural forces, resulted in inner tensions that all worked their way out in warps as the boards dried.

I learned that I myself had a great deal to do with how much of a tree’s old realities came through the saw to haunt the boards in that new reality. The sawyer’s first responsibility to the carpenter lay in keeping that whirling convocation of molecules that was the saw as close to Euclid’s abstract vertical plane as possible. Mostly this was a mater of learning how, and how often, to sharpen the saw’s teeth. These were basically little chisels, forty or so of them, a little wider than the width of the blade, that chew at the wood with a sharp sna-a-acking sound when they are sharp.

But when the teeth grow dull, or get chipped by a pebble in the bark (or some righteous ecoteur’s nail), or even when they are not sharpened straight, all sorts of increasingly ugly things begin to happen. The saw lugs down in the wood; the machinery begins to strain. And if one side of the teeth grows worse than the other side, the saw begins to bend toward the dull side, wandering off into a warpedy plane that changes the dimensions of the board – but worse, causes the saw to rub against the wood on one side or the other, creating friction and heat.

The saw always had a thin jet of water playing on it to keep it cool, but twelve square feet of steel rubbing all the way along a sixteen-foot log can generate a powerful amount of heat, which causes the hot part of the saw to expand, which throws off that delicate molecular balance, and the saw begins to beat against the air again – and if you stupidly try to run it into the log again, it can turn into the most frightening piece of powerful chaos I have ever approached, with a handful of snow or a cup of water to put against it, to extract the heat and again return it to Euclid’s smooth hissing plane.

So I learned quickly that, even though sharpening was a tedious job that produced no boards, the quality of both the lumber and the experience of cutting it depended absolutely on sharpening. Hit a rock at, say, eleven-thirty and try to saw on through to lunchtime before shutting down to sharpen, and it would be one long lousy hour. If you ever buy rough-sawn lumber that varies more than a quarter-inch in its dimensions from one end to the other, you are probably buying lumber cut during an hour like that – lumber that was quite literally born in an atmosphere of “bad vibes.” Don’t build it into your walls.

I began to learn too that how I started into a log had a lot to do with the quality of the lumber. Being natural things, growing out of naturally uneven and hilly terrain, pushed by snow and wind and the presence of other trees, no tree grows perfectly straight; they are all a little bent by life, and that history is going to translate into a “crown” or bow in the boards that come through the gate between nature’s world and ours. The internal tensions of trees can be amazing. Cutting 6×6 fence posts from the buttlog of a gnarled old sidehill douglasfir once, I saw the log squeeze down so powerfully on the saw that it would have stalled it and burned out the motor, had I not hastily backed out of the cut.

The trick was to try to peel the boards off the log in a way that would result in the board warping mostly along only one of its dimensions (preferably its thickness) rather than warping along both its thickness and width dimensions, which meant that the most important moment there at the gate between the natural and cultural worlds was when I levered the log with my cant hook off the deck and onto the saw carriage; I had to make a quick judgement before clamping the log with the “dogs” and sending it into the saw. By learning how to read the log – and caring enough for the tree that had been, to want the boards to be worthy of its memory – I learned I could minimize the extent to which the tree’s problems in the natural world become the carpenter’s problems in the cultural world.

I’d gone to the sawmill to work because Pipher had said he wanted to shut it down in the winter, which meant writing time, but I approached the work with a culturally-induced sense that it was a little beneath me – a world less intelligent than the one I, a college-educated up-and-coming writer (so I still thought of myself then), was really fitted for.

But as I began to really get into the work – the applied geometry of the work – I began to realize that it was the most intellectually demanding job I had ever had, and in a larger moral sense, perhaps the most responsible. Aside from the responsibility of keeping my own limbs out of the machinery, I had a responsibility to the carpenters who would be stuck with the boards, and I had a responsibility to the trees, to do as good a job as possible in making their broken bodies at least useful, and maybe beautiful in the way that a good house, or even a good outhouse, can be beautiful.

I left the mill after two-plus years, mostly because business got too good. I went there in part because it was promised as a part-time job, shutting down in the winter, which I wanted for writing. But because we had a great functional assemblage of junk, and because I was basically a tree-hugger at heart who cared a lot about doing the work right, we were turning out good lumber. We had one customer – a developer/builder from Gunnison, who started leaving a trailer at the yard, telling us to just call him when we had it full of 16-foot two-by-sixes, which he was using in his houses. With half-dried rough-sawn lumber, you just use bigger nails.

But the upshot of that was that Pipher decided he wanted to run the mill year round, and there went the writing season. So I left.

In addition, I had began to see how mill accidents happen, in my own growing casualness toward the potentially deadly machinery I worked a few feet from – like the fact that it had become a mundane act to go up to the overheated air-beating saw with a handful of snow or cup of water to soothe it down. Statistics indicate that most mill accidents happen not to newcomers but to people who have been too long in the mill. Industrial workers start to put themselves through those gates, as it were – fingers, feet, hands, and all the knotty warpedy slices that come off the soul when one hangs around anywhere too long after starting to feel like just another piece of the machinery.

I loved geometry in school; I liked rediscovering it at the mill; but I am worried that too much time in a Euclidean environment – all the rough evolved textures and shapes of accommodative nature sliced and shaved down to featureless planes and predictable angles – might eventually reduce me, much as I reduced the trees, to some human analogy of the uniform standard two-by-four.

But still – I’ll still say today, three decades later – I’ve never had work before or since that required such a balance of mental and physical work, and such a high level of dual responsibility, as I did at that job at the gate between the worlds, the natural world of the tree and the cultural world of the board.

***